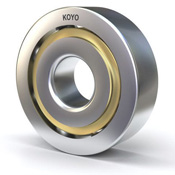

Matched Pair bearings are Angular contact ball bearings that are suitable for applications that require high accuracy and high-speed performance. Bearings with a smaller contact angle are more suitable for high-speed rotation; those with a larger contact angle are more suitable for high load applications. Angular contact ball bearings are often preloaded to enhance their rigidity and rotating performance. For high-precision matched pair angular contact ball bearings of class 5 or higher, which are used in machine tools and other precision equipment, the standard preload is specified in three levels: light, medium, and heavy. Two bearings are used together facing one another or two or more bearings are matched and used.

Depending on the requirements matched pairs can be supplied in three different arrangements:

Tandem arrangement

A tandem arrangement is used when the load carrying capacity of a single bearing is inadequate. When arranged in tandem, the load lines are parallel and the radial and axial loads are equally shared by the bearings. Axial loads in both directions can be accommodated.

Back-to-back arrangement

Mounting two bearings back-to-back provides a relatively stiff bearing arrangement, which can also accommodate tilting moments. When arranged back-to-back, the load lines diverge towards the bearing axis. Axial loads in both directions can be accommodated, but only by one bearing in each direction.

Face-to-face arrangement

Mounting two bearings face-to-face is not as stiff as a back-to-back arrangement, but less sensitive to misalignment. When arranged face-to-face, the load lines converge towards the bearing axis. Axial loads in both directions can be accommodated, but only by one bearing in each direction.

"V-shaped" marking

A "V-shaped" marking on the outside surface of the outer rings of matched bearings (fig. 5) indicates how the set should be mounted to obtain it's desired performance . The bearing pairs are supplied as a packaged unit.